86-021-54422420 13818829143

86-021-54422402 17701898099

86-021-54422420 13818829143

86-021-54422402 17701898099

All products

联轴器

联轴器 Coupling

传动轮

传动轮 Pulley

胀套

胀套 Lock

丝杆导轨

丝杆导轨 ScrewGuide

离合制动器

离合制动器 Clutch

传动器

传动器 Actuators

皮带

皮带 Belt

电机

电机 Motor

轴承

轴承 Bearing

链轮分为主动链轮和从动链轮,主动链轮通过花键的形式装在发动机输出轴上;通过链条将动力传递给驱动轮,一般主动链轮比从动链轮要小,可起到降速增扭的效果。

直孔链轮的优势特征:

1、链轮可适合长时间大扭力下工作,传递性能稳定。

2、链轮大小轮传动变化时产生速比的变化。

3、链轮易安装,好维护和方便润滑,属于实惠耐用传动元件。

4、链轮使用SC45钢或锻钢,可附加工条件:调质淬火,发黑防锈处理。

5、批量生产加工周期:2~3周。

链轮广泛应用于农业机械、建筑机械、石油机械、采矿、起重、金属切削机床等行业机械。

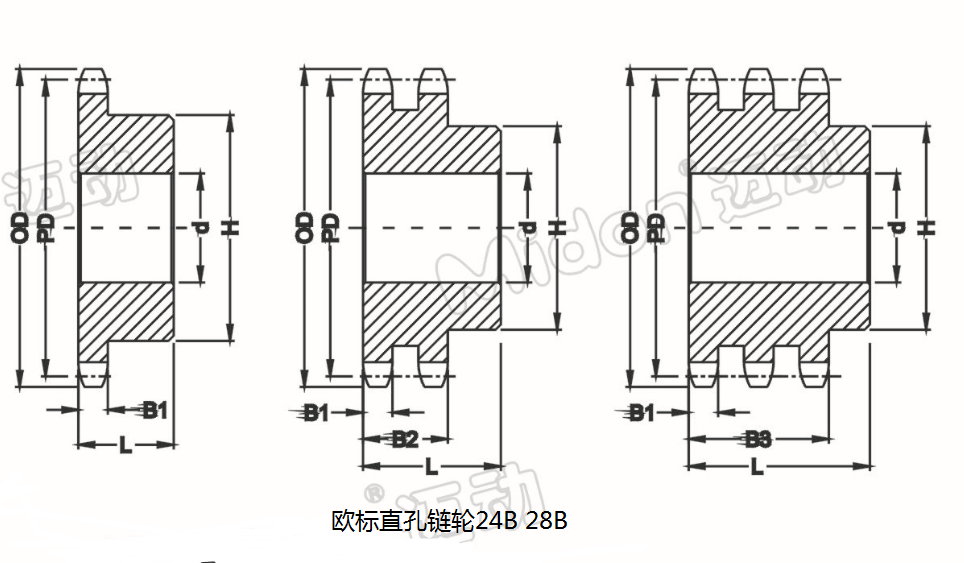

| 欧标24B系列链轮 | 欧标28B系列链轮 | |||||||||||||||

| 节距(Pitch)=38.1(mm)=1 1/2" | 节距(Pitch)=44.45(mm)=1 3/4" | |||||||||||||||

| 齿数Teeth | 外径O.D | 节径P.D | B型凸台Hub | 最大孔径 | 重量 W.t | 齿数Teeth | 外径O.D | 节径P.D | B型凸台Hub | 最大孔径 | 重量 W.t | |||||

| 毂径H | 轮厚L | Bore Max | B型. Kg | A型. Kg | 毂径H | 轮厚L | Bore Max | B型. Kg | A型. Kg | |||||||

| 9 | 126.40 | 111.4 | 69 | 45 | 46 | 2.02 | 1.69 | 11 | 176.30 | 157.77 | 112 | 70 | 75 | 5.27 | 3.18 | |

| 10 | 138.00 | 123.29 | 80 | 45 | 54 | 2.61 | 1.88 | 12 | 189.30 | 171.74 | 125 | 70 | 84 | 6.40 | 3.95 | |

| 11 | 150.00 | 135.23 | 90 | 50 | 60 | 3.77 | 20.60 | 13 | 204.20 | 185.74 | 140 | 70 | 94 | 8.22 | 4.31 | |

| 12 | 162.00 | 147.21 | 102 | 50 | 68 | 4.77 | 2.68 | 14 | 218.20 | 199.76 | 140 | 60 | 94 | 9.13 | 4.77 | |

| 13 | 174.20 | 159.2 | 114 | 50 | 76 | 5.91 | 30.60 | 15 | 232.30 | 213.79 | 160 | 60 | 107 | 11.40 | 5.45 | |

| 14 | 186.20 | 171.22 | 127 | 60 | 84 | 6.68 | 3.72 | 16 | 246.30 | 227.84 | 160 | 64 | 107 | 12.76 | 6.81 | |

| 15 | 198.20 | 183.25 | 140 | 60 | 94 | 7.49 | 4.31 | 17 | 260.00 | 241.91 | 160 | 64 | 107 | 13.65 | 7.71 | |

| 16 | 210.30 | 195.29 | 140 | 60 | 94 | 9.08 | 4.86 | 18 | 274.00 | 255.98 | 160 | 64 | 107 | 13.65 | 8.63 | |

| 17 | 222.30 | 207.35 | 140 | 60 | 94 | 9.76 | 5.44 | 19 | 289.00 | 270.06 | 160 | 64 | 107 | 15.01 | 9.53 | |

| 18 | 234.30 | 219.41 | 140 | 60 | 94 | 10.49 | 6.13 | 20 | 303.00 | 284.14 | 160 | 64 | 107 | 16.84 | 10.44 | |

| 19 | 246.50 | 231.48 | 140 | 60 | 94 | 11.21 | 7.03 | 21 | 317.00 | 298.24 | 160 | 64 | 107 | 18.19 | 11.79 | |

| 20 | 258.60 | 243.55 | 140 | 60 | 94 | 12.26 | 7.94 | 22 | 331.00 | 312.34 | 160 | 64 | 107 | 19.11 | 13.17 | |

| 21 | 270.60 | 255.63 | 140 | 60 | 94 | 13.38 | 8.62 | 23 | 345.00 | 326.44 | 160 | 64 | 107 | 20.46 | 14.06 | |

| 22 | 282.70 | 267.72 | 140 | 60 | 94 | 13.67 | 9.76 | 24 | 359.00 | 340.54 | 160 | 64 | 107 | 21.84 | 15.44 | |

| 23 | 294.80 | 279.8 | 140 | 60 | 94 | 14.74 | 10.43 | 25 | 373.00 | 354.65 | 160 | 64 | 107 | 22.73 | 16.78 | |

| 24 | 306.80 | 291.9 | 140 | 60 | 94 | 15.48 | 11.35 | 26 | 387.00 | 368.77 | 160 | 64 | 107 | 26.83 | 18.61 | |

| 25 | 319.00 | 303.99 | 140 | 60 | 94 | 16.38 | 12.47 | 27 | 401.00 | 382.88 | 160 | 64 | 107 | 27.74 | 20.43 | |

| 26 | 331.00 | 316.09 | 150 | 65 | 100 | 19.43 | 13.39 | 28 | 416.00 | 397.00 | 160 | 64 | 107 | 30.29 | 20.88 | |

| 27 | 343.20 | 328.19 | 150 | 65 | 100 | 20.39 | 14.53 | 30 | 444.00 | 425.24 | 160 | 64 | 107 | 32.73 | 25.17 | |

| 28 | 355.20 | 340.29 | 160 | 65 | 107 | 21.34 | 15.89 | 32 | 472.00 | 453.49 | 178 | 76 | 120 | 34.84 | 31.02 | |

| 29 | 367.30 | 352.39 | 160 | 65 | 107 | 22.79 | 17.02 | 38 | 557.00 | 538.27 | 178 | 102 | 120 | 51.25 | 48.58 | |

| 30 | 379.50 | 364.49 | 160 | 65 | 107 | 24.25 | 18.39 | 40 | 585.00 | 566.54 | 178 | 102 | 120 | 52.84 | 52.8 | |

| 31 | 391.60 | 376.6 | 160 | 65 | 107 | 26.19 | 20.02 | 42 | 613.50 | 594.81 | 178 | 102 | 120 | 54.43 | 57.02 | |

| 32 | 403.70 | 388.71 | 160 | 65 | 107 | 28.12 | 21.66 | 45 | 656.00 | 637.22 | 178 | 102 | 120 | 60.55 | 63.35 | |

| 33 | 415.80 | 400.82 | 160 | 65 | 107 | 30.05 | 23.29 | 48 | 698.00 | 679.63 | 178 | 102 | 120 | 62.72 | 69.68 | |

| 34 | 427.80 | 412.93 | 160 | 65 | 107 | 31.99 | 24.93 | 54 | 783.00 | 764.47 | 178 | 127 | 120 | 74.60 | 82.34 | |

| 35 | 440.00 | 425.04 | 160 | 65 | 107 | 33.93 | 26.56 | 57 | 832.34 | 806.89 | 178 | 127 | 120 | 81.77 | 88.67 | |

| 36 | 452.00 | 437.15 | 160 | 65 | 107 | 35.86 | 28.19 | 60 | 869.00 | 849.32 | 178 | 127 | 120 | 88.94 | 97.97 | |

| 38 | 476.20 | 461.37 | 160 | 65 | 107 | 39.73 | 31.46 | 68 | 988.11 | 962.47 | 191 | 127 | 133 | 108.05 | 122.79 | |

| 40 | 500.60 | 485.6 | 160 | 65 | 107 | 42.52 | 36.23 | 72 | 1044.74 | 1019.04 | 191 | 127 | 133 | 117.61 | 135.19 | |

| 42 | 524.70 | 509.83 | 160 | 95 | 107 | 45.31 | 40.99 | 76 | 1101.37 | 1075.62 | 191 | 127 | 133 | 127.17 | 147.6 | |

| 45 | 561.20 | 546.19 | 160 | 95 | 107 | 50.71 | 48.14 | 95 | 1370.32 | 1344.39 | 191 | 127 | 133 | 172.57 | 206.53 | |

| 48 | 597.40 | 582.54 | 160 | 102 | 107 | 57.43 | 55.29 | |||||||||

| 50 | 621.70 | 606.378 | 160 | 102 | 107 | 61.57 | 60.05 | |||||||||

| 54 | 670.20 | 655.26 | 160 | 102 | 107 | 69.84 | 69.58 | |||||||||

| 57 | 706.50 | 691.62 | 160 | 102 | 120 | 76.05 | 76.73 | |||||||||

| 60 | 742.80 | 727.99 | 178 | 102 | 120 | 80.05 | 85.19 | |||||||||

| 68 | 846.95 | 824.97 | 178 | 102 | 120 | 93.39 | 107.74 | |||||||||

| 72 | 895.49 | 873.43 | 178 | 102 | 120 | 111.51 | 119.02 | |||||||||

| 76 | 944.03 | 921.96 | 191 | 114 | 133 | 129.62 | 130.30 | |||||||||

| 95 | 1174.56 | 1152.33 | 191 | 114 | 133 | 215.67 | 183.88 | |||||||||

| 96 | 1186.69 | 1164.46 | 191 | 114 | 133 | 220.20 | 186.70 | |||||||||

| 114 | 1405.06 | 1382.72 | 191 | 114 | 133 | 301.71 | 237.46 | |||||||||

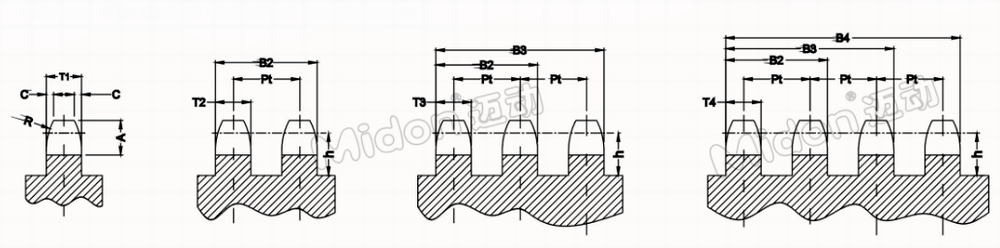

| 链轮排齿参数(美标、欧标) | |||||||||||||||

| 美标 | |||||||||||||||

| 链轮号 | 节距 | 滚子直径 | 齿节高 | 倒角高 | 倒角宽 | 弧半径 | 齿厚(1~4排) | 齿幅(2~3排) | 齿幅(4排) | 排距 | |||||

| SPROCKET NO: | pitch | Roller Dia | h | A | C | R | T1 | T2/T3 | T4 | B2 | B3 | B2 | B3 | B4 | Pt |

| 25 | 6.35 | 3.30 | 4.0 | 3.2 | 0.8 | 6.8 | 2.8 | 2.7 | 2.4 | 9.1 | 15.3 | 8.8 | 15.2 | 21.6 | 6.4 |

| 35 | 9.525 | 5.80 | 5.0 | 4.8 | 1.2 | 10.2 | 4.3 | 4.1 | 3.8 | 14.2 | 24.4 | 13.9 | 24 | 34.1 | 10.1 |

| 41 | 12.70 | 7.77 | 7.0 | 7.0 | 1.1 | 19.2 | 2.8 | 一 | 一 | 一 | 一 | 一 | 一 | 一 | 一 |

| 40 | 12.70 | 7.92 | 7.0 | 6.4 | 1.6 | 13.5 | 7.2 | 7.0 | 6.5 | 21.4 | 35.8 | 20.9 | 35.3 | 49.7 | 14.4 |

| 50 | 15.875 | 10.16 | 10.3 | 7.9 | 2.0 | 16.9 | 8.7 | 8.4 | 7.9 | 26.5 | 44.6 | 26 | 44.1 | 62.2 | 18.1 |

| 60 | 19.05 | 11.91 | 11.8 | 9.5 | 2.4 | 20.3 | 11.7 | 11.3 | 10.6 | 34.1 | 56.9 | 33.4 | 56.2 | 79.0 | 7.0 |

| 80 | 25.40 | 15.88 | 15.5 | 12.7 | 3.2 | 27.0 | 14.5 | 14.1 | 13.1 | 43.4 | 72.7 | 42.6 | 71.9 | 101.2 | 29.3 |

| 100 | 31.75 | 19.05 | 19.2 | 15.9 | 4.0 | 33.8 | 17.5 | 17.0 | 16.0 | 52.8 | 88.6 | 51.8 | 87.6 | 123.4 | 35.8 |

| 120 | 38.10 | 22.22 | 23.0 | 19.1 | 4.8 | 40.5 | 23.5 | 22.7 | 21.5 | 68.1 | 113.5 | 66.9 | 112.3 | 157.7 | 45.4 |

| 140 | 44.45 | 25.40 | 27.0 | 22.2 | 5.6 | 47.2 | 23.5 | 22.7 | 21.5 | 71.6 | 120.5 | 70.4 | 119.3 | 168.3 | 48.9 |

| 160 | 50.80 | 28.58 | 31.6 | 25.4 | 6.4 | 54.0 | 29.3 | 28.4 | 27.0 | 86.9 | 145.4 | 85.5 | 144 | 202.5 | 58.5 |

| 180 | 57.15 | 35.71 | 36.8 | 28.5 | 7.2 | 61.0 | 33.1 | 32.0 | 30.4 | 97.8 | 163.6 | 96.2 | 162 | 227.8 | 65.8 |

| 200 | 63.50 | 39.67 | 39.6 | 31.8 | 7.9 | 67.5 | 35.5 | 34.1 | 32.5 | 105.7 | 177.3 | 104.1 | 175.7 | 247.3 | 71.6 |

| 240 | 76.20 | 47.62 | 48.5 | 38.1 | 9.5 | 81.0 | 44.1 | 42.7 | 40.7 | 130.5 | 218.3 | 128.5 | 216.3 | 304.1 | 87.8 |

| 欧标(A、B系列链轮主要参数) | |||||||||||||||

| 链轮号 | 节距 | 滚子直径 | 齿节高 | 倒角高 | 倒角宽 | 弧半径 | 齿厚(1~4排) | 齿幅(2~4排) | 排距 | ||||||

| SPROCKET NO: | pitch | Roller Dia | h | A | C | R | T1 | T2/T3 | T4 | B2 | B3 | B4 | Pt | ||

| 4B | 6 | 4 | 4.1 | 3 | 0.6 | 6 | 2.6 | 2.5 | 2.4 | 一 | 一 | 一 | 一 | ||

| 5B | 8 | 5 | 5.3 | 4 | 0.8 | 8 | 2.8 | 2.7 | 2.6 | 8.3 | 13.9 | 19.4 | 5.6 | ||

| 6B | 9.525 | 6.35 | 6.2 | 4.8 | 1 | 10 | 5.3 | 5.2 | 5.0 | 15.4 | 25.6 | 35.6 | 10.2 | ||

| 8B | 12.70 | 8.51 | 8.4 | 6.4 | 1.3 | 13 | 7.2 | 7.0 | 6.8 | 21.0 | 34.9 | 48.5 | 13.9 | ||

| 10B | 15.88 | 10.16 | 10.2 | 7.9 | 1.6 | 16 | 9.1 | 9.0 | 9.0 | 25.6 | 42.2 | 58.8 | 16.6 | ||

| 12B | 19.05 | 12.07 | 11.2 | 9.5 | 2 | 19 | 11.1 | 10.8 | 10.9 | 30.4 | 49.9 | 69.4 | 19.5 | ||

| 16B | 25.40 | 15.88 | 14.6 | 12.7 | 2.5 | 26 | 16.2 | 15.8 | 15.8 | 47.7 | 79.6 | 111.5 | 30.9 | ||

| 20B | 31.75 | 19.05 | 18.0 | 15.9 | 3.5 | 32 | 18.5 | 18.2 | 18.2 | 54.6 | 91.0 | 127.5 | 36.5 | ||

| 24B | 38.10 | 25.40 | 22.4 | 19.1 | 4 | 38 | 24.1 | 23.6 | 23.6 | 72.0 | 120.3 | 168.7 | 48.4 | ||

| 28B | 44.45 | 27.94 | 24.9 | 22.2 | 5 | 44 | 29.4 | 28.8 | 28.8 | 88.4 | 148.0 | 207.6 | 59.6 | ||

| 32B | 50.80 | 29.21 | 28.2 | 25.4 | 6 | 51 | 29.4 | 28.8 | 28.8 | 87.4 | 146.0 | 204.6 | 58.6 | ||

| 40B | 63.50 | 39.37 | 34.9 | 31.8 | 8 | 64 | 36.2 | 35.4 | 35.4 | 107.7 | 180.0 | 252.3 | 72.3 | ||

| 48B | 76.20 | 48.26 | 41.8 | 38.1 | 9 | 76 | 43.3 | 42.5 | 42.5 | 133.7 | 224.9 | 316.1 | 91.2 | ||

| 56B | 88.90 | 53.98 | 50.2 | 44.5 | 11 | 89 | 50.7 | 49.6 | 49.6 | 156.2 | 262.8 | 369.4 | 106.6 | ||

| 64B | 101.60 | 63.50 | 57.8 | 50.8 | 13 | 102 | 57.9 | 56.7 | 56.7 | 176.6 | 296.5 | 416.4 | 119.9 | ||

| 72B | 114.30 | 72.39 | 66.0 | 57.2 | 15 | 114 | 65.2 | 63.8 | 63.8 | 200.1 | 336.4 | 472.7 | 136.3 | ||

链轮的安装要求:

1、根据规范精确选用传动链轮类型。

2、按精确方法将主、从动链轮设备到位,且拧紧紧固件使其到达规矩力矩恳求。

3、装上传动链条并调整好松紧度后,检查链条与链轮配合是不是顺利、共面,且与链罩无干与。

4、检查设备传动链轮的方位(变速器输出副轴、轮毂等)情况是不是杰出,否则须维修或更换有关件。

链轮使用过程中的注意事项:

1、从动链轮应有防松方法与措施。

2、链轮和链条最好一起更换,若只更换其中之一,会加剧两头的磨损。

3、要守时地清洗及光滑传动链条、传动链轮,以前进其运用寿命。

4、从动链轮装车后,应使用调节器和后摇架刻线将后轮轴调正,这么既可避免后轮跑偏,也能避免链轮与链条的早期磨损。

公司名称:上海迈动机电设备有限公司

公司地址:上海青浦工业区崧海路98号

邮政编码:201703

公司电话:021-54422420

公司传真:021-54422420-801

邮箱:shmidon@126.com

户名:上海迈动机电设备有限公司

税号:310112660703692

开户行:工行上海莘庄支行

账号:1001140209007024765

电话:021-54422420 54422402

传真:021-54422420-801

地址:上海莘庄工业园区申富路128号(开票)

地址:上海青浦工业园区崧海路98号(收货地址)

上海迈动机电设备有限公司提供17%的增值税发票;

品质100%保证,让你更放心使用。

ADD:上海迈动机电设备有限公司 备案号:沪ICP备15037005

TEL:86-021-54422420,021-544227902 ,021-54422402 MB:13818829143,17701898099